INTRODUCTION

|

| Brushed motor mounted in RC Vehicle |

Proper break-in and maintenance can improve performance and extend the life of the motor.

The break-in procedure basically seats the brushes to the commutator.

There are numerous opinions on how to properly break-in a brushed motor, the most common being the wet method, in which the motor is placed into clean water, and ran for a period of time to seat the brushes, the water keeps the motor cool and actually flushes out any excess debris derived from the process.

As the motor is run, often in dirty or wet environments, good general maintenance practices can be utilized after running to maintain performance and longevity of the motor.

The purpose here is to give some good general break-in and brushed motor maintenance practices to help users prolong the life of their brushed motors.

Breaking in a Brushed Motor

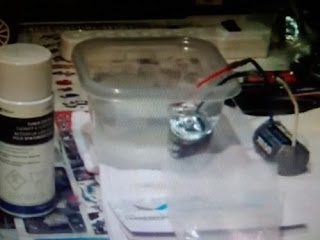

|

| Breaking in Brushed Motor in Distilled Water |

Note: These are the 2 most common methods used for break-in.

Wet Method - Never use this procedure on brushless motors

What you will need - Distilled Water or Rubbing Alcohol, Electronic Contact Cleaner, Motor Bearing oil and 2 "D" size batteries with wire and alligator clips.

1) First things first if your motor is mounted in your RC vehicle you will want to disconnect the wire leads and remove it from the motor mount, if you are replacing a motor go ahead and perform the break-in process before installing the motor.

Note: You may need to remove the pinion gear before you can remove the motor.

3) Let the motor run 20 to 30 minutes.

4) Disconnect the battery leads from the motor, you will notice that the water is fairly dirty due to the carbon particles that have been carried away from the motor.

|

| Applying Bearing Oil to Rotor Shaft Bushings |

6) Apply a drop of bearing oil on the bushings or bearings of the motor shaft on the front and rear of the motor. Then apply a drop of oil on the inside of the motor on the commutator, and rotate the shaft by hand to distribute the oil.

7) Install the motor and set the gear mesh, many use the paper method for proper alignment.

Dry Method

2) Get your battery and motor hooked back up as if it were in the RC vehicle.

3) You will now use the throttle trim on your transmitter to run the motor at an extremely slow speed, you don't want to run the motor at high speeds with a wet or dry break-in.

4) Let the motor run for 20 or 30 minutes.

5) Disconnect the motor.

6) Spray the whole inside of the motor with electronic contact cleaner until the liquid running out is clear.

7) As in the wet method, apply a drop of bearing oil on both ends of the motor on the bushing or bearing.

Apply 1 drop of oil on the commutator inside the motor, then rotate the shaft by hand to distribute the oil.

8) Install the motor and set the gear mesh according to specs.

GENERAL BRUSHED MOTOR MAINTENANCE

|

| Traxxas Rustler RC Car in the Dirt |

The type of conditions you run in will determine how often the motor will need to be cleaned.

If you have a motor with a sealed can, you will not be able to access the motor.

1) Remove the motor from the RC vehicle

2) Clean the exterior of the can with a soft bristle brush and cleaner, be sure to remove any dirt or debris around the bushing or bearings on both ends of the motor.

3) If you have access to compressed air you can blow the bulk of the dust and debris out of the motor with air, then clean the inside of the motor by spraying electronic contact cleaner into the various port holes until the liquid coming out is clear. Dry the motor off with towels.

4) Apply one drop of bearing oil on the bushings or bearings on each end of the motor, put a drop of oil on the commutator inside the motor. Spin the motor shaft a couple of times.

5) Install the motor and set the gear mesh to specs. (Paper method is common)

Final Thoughts

A brushed motor is not going to last forever, but with some preventative maintenance you give yourself a chance to get the maximum life out of your brushed motors.

Dirt, mud, dust, and debris will certainly shorten the life of the motor, some preventative maintenance can save you in the long run.

No comments:

Post a Comment